Why Does My EPOXY54 Epoxy Look “Dried Up”? (And How to Fix It)

Share

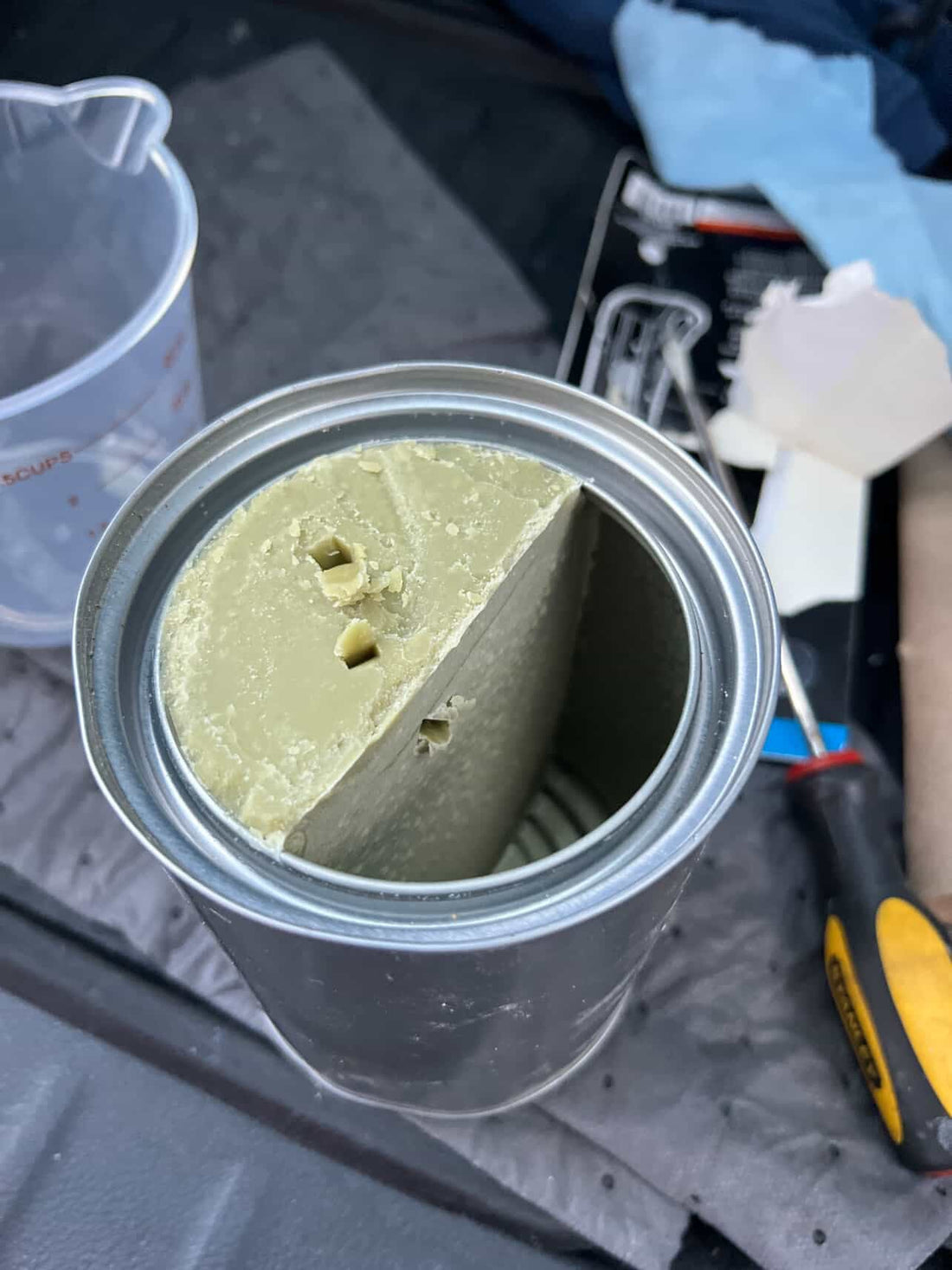

From time to time, customers notice that their EPOXY54 Aluminum Block Epoxy resin looks thicker than usual, or even appears as if it has “dried up” in the can. This often happens after shipping in cold conditions (especially by air freight) or when the product is stored in a cooler environment.

The good news? It’s not drying out at all — and it never can.

Why It Happens

EPOXY54’s resin is sensitive to temperature changes.

-

At colder temperatures, the epoxy can thicken and take on a cloudy, semi-solid appearance.

-

This does not mean the product has expired or cured — in fact, it’s impossible for the resin to cure or dry without its hardener.

How to Fix It

Restoring your epoxy to its normal liquid state is quick and easy:

-

Gently warm the container using a hair dryer or heat gun.

-

Apply heat evenly until the resin flows smoothly again.

-

Avoid overheating — moderate warmth is all that’s needed.

Once warmed, the epoxy will return to its normal consistency and is ready to use.

What Happens When You Mix It

When you combine the resin with the hardener, a chemical reaction begins.

-

This reaction naturally generates heat, making the mixture more fluid and easier to pour.

-

As it cures, the epoxy will change from its natural green color to the signature blue finish you see on our website.

Best Practice for Storage

-

Store at room temperature whenever possible

-

Avoid leaving cans in cold garages, vehicles, or unheated storage areas

-

If your resin does thicken, remember: a little warmth is all it takes to restore it

Our Promise

At EPOXY54, we stand behind our product. A resin that looks thicker or “dried up” is still 100% usable and will cure to the same high-performance blue finish every time.

So next time your epoxy looks thicker after a cold shipment, just know: a little heat brings it right back to life — and it can never cure until you mix it with the hardener.